What is a Tech Pack and Why You Need One Before You Sample

The Fashion Tech Pack serves as an essential production document which clarifies manufacturing processes, materials, and expectations to ensure everyone is following one source of truth.

If you’re preparing to launch a fashion line, you may have heard of the term “tech pack”—but what exactly is it, and why is it so important?

A tech pack is the master document that communicates every detail of your garment to your manufacturer. It’s the blueprint your factory needs to bring your ideas to life accurately, efficiently, and cost-effectively.

Skipping this step or sending an incomplete tech pack can lead to costly mistakes, poor-quality samples, and major delays. Whether you’re developing your very first sample or scaling your production, a detailed tech pack is essential for success.

What Exactly Is a Tech Pack?

A tech pack is a detailed instruction manual for your garment. It includes everything from flat sketches and fabric details to size measurements, construction details, and packaging instructions.

Tech packs are used by everyone in the production chain. That includes designers, patternmakers, factories, and quality control teams, to ensure that nothing gets lost in translation and that expectations are clearly communicated.

At AJG, we often say that a tech pack is your product’s single source of truth. It ensures consistent communication, quality, and pricing throughout your development cycle. This document operates as a reference point that designers and manufacturers and vendors use to maintain clear understanding at every stage of production.

Cover Page

This page contains a brief description which explains the product features for easy reference.

Style Name/Number A unique garment identifier. Use our helpful assortment planning template for tips on keeping track of style numbers and skus.

Design Sketch Clear, technical sketch of the final product showing seam placement, stitch types, and overall construction

Contact Information Details of designers, factories, and key contacts.

Revision History Log of all changes and updates made during tech pack creation to make sure everyone in the supply chain is aware of changes made to the document.

Detail Page

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

This section delivers all the details about how the garment should be built - including fabric placement, construction details, stitch types, and more. Detailed line drawings, called Tech Sketches or Flats, are different than your aesthetic sketches - they are “flat” without added flourish, and often laid on a tech croquis to clearly show scale and seam placement. Annotate these sketches with construction notes and reference photos to communicate your intention clearly. These pages help explain what makes your garment unique—such as a special pleat, stitch detail, or hardware placement.

Learn how tech sketches are developed in the Design Process chapter of our Fashion Entrepreneur’s Toolkit, and get a head start with our easy to use Tech Pack Template.

Technical Sketch (Flats): Line drawings that show precise scale, shape, and details along with accurate stitch locations.

Construction Call-outs: Instructions on stitches, seams, and special construction details.

Reference Images: The reference images provide visual demonstrations of unique details and special finishes for better understanding - remember, a picture speaks a thousand words! Use references if you don’t know the exact term for something to help communicate exactly what you want.

Spec (Measurement) Page

Spec Pages, or Measurement Charts, are essential to ensuring your garment’s success. Providing clear points of measurement, along with how to measure certain areas of the garment, ensure your patternmaker can execute the design clearly. Be sure to include measurements for each size, called “graded specs”, along with how-to-measure diagrams, as well as tolerances. This section ensures your fit remains consistent across sizes and production runs.

Base Size: When you begin development, you will focus on one size to streamline sampling and testing. This is called your “base size”. This should be your size, or a designated fit model’s size, to ensure consistency in testing and providing comments. Once the base size measurements are approved, your patternmaker can help add the measurements for the other sizes. Read more about choosing a fit model, and learn key tips on fitting your garments in our Guide to Successful Garment Fitting.

Tolerances: Remember, sewing is a human process. While some parts of the production line are automated, many hands will touch your garment on it’s journey to being assembled. This means there can be some variances in certain measurements and details. Tolerances outline allowable measurement variations to manage manufacturing discrepancies. Your factory may have their own tolerance standards, but it’s okay to negotiate or set expectations for critical points of your garment to ensure the outcome is satisfactory.

How To Measure: While some measurements may be self explanatory, it may be helpful to create a visual outline of how to measure certain areas of your garment to ensure everyone is on the same page.

Grade Rules: Defines measurement changes across sizes, often created by your pattern maker to ensure accurate size adjustments and fit consistency.

Bill of Materials (BOM) Page

The Bill of Materials page clearly compiles all of the details of each material used on the style. It includes supplier information, content, weight, color, size, or any other defining information needed. This is broken down by colorway to show what colors of each trim are used on each colorway of your style. Ensure the placement of each item is noted either in a column or on a separate trim/detail page.

Fabrics: Clearly document the fabric, content, weight, supplier, and any. other details to ensure the correct fabric is used.

Trims Quantities and specifics of buttons, zippers, labels, etc.

Thread Specific type and color needed.

Packaging: All packaging requirements including care labels, hang tags, care labels, etc. along with where to place them on the garment.

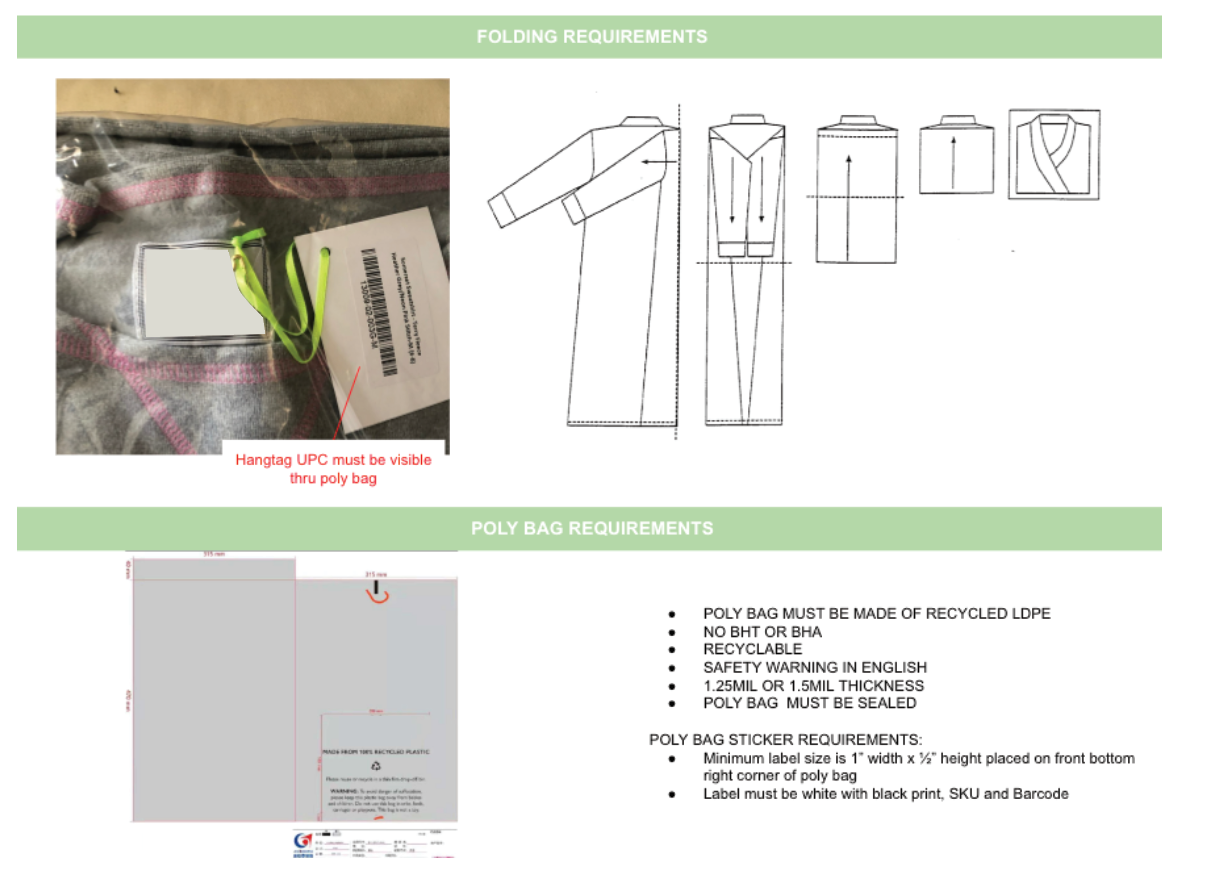

Packaging Requirements

Ensure your factory is clear on the final folding and packaging requirements - how the garment should be presented in the polybag, or if you require shipped on hangers. If your warehouse has specific box dimension requirements or labeling requirements such as barcodes, be sure to include those as well.

Why a Tech Pack Matters: Precision and Consistency

When you're designing a collection, it's easy to think the biggest challenge is choosing the perfect fabric or nailing a signature silhouette. But if you ask anyone who’s brought a product to life, they’ll tell you that real success comes down to communication. That’s where your tech pack becomes your most valuable asset.

Your tech pack is more than a design file, it’s your product’s single source of truth. Every measurement, material, and construction detail lives in one place, making it easier for everyone from patternmakers to production managers to work from the same references. When you're juggling fit samples, supplier emails, and looming deadlines, that kind of clarity can make or break your product’s execution.

It’s also your insurance policy. If something goes wrong in production, such as a logo is in the wrong spot or your neckline comes out too wide, your tech pack gives you a paper trail to fall back on. It’s not just documentation but your proof of what was agreed upon, and a tool for accountability when you need it most.

Consistency is another huge win. A solid tech pack keeps your product fit tight across sizes and seasons, and lets you reproduce styles again, whether you’re scaling with a new factory or relaunching a bestseller next year. Even third-party quality inspectors will use your tech pack as the standard during final checks.

When your product is touched by a dozen different hands, your tech pack is where they can all look to know what’s expected. It streamlines communication, protects your brand integrity, and makes scaling so much simpler. It also keeps all of your hard work and knowledge stored in one place, ensuring you have ownership of your intellectual property.

Need a place to start? Our Tech Pack Template is the exact format we use with our own clients, filled with helpful tips and tricks designed to grow with your brand.

→ Want help putting yours together? Reach out—our team can support you every step of the way.

Build Your Brand with AJG

AJG Fashion Consulting helps brands create complete tech packs that enable smooth manufacturing operations leading to market success. With our helpful guidance and expertise, we can transform your dreams into into high-quality garments from initial sketches through to delivery. Book a consultation with us today, and let us help you bring your vision to life.